Production Machining

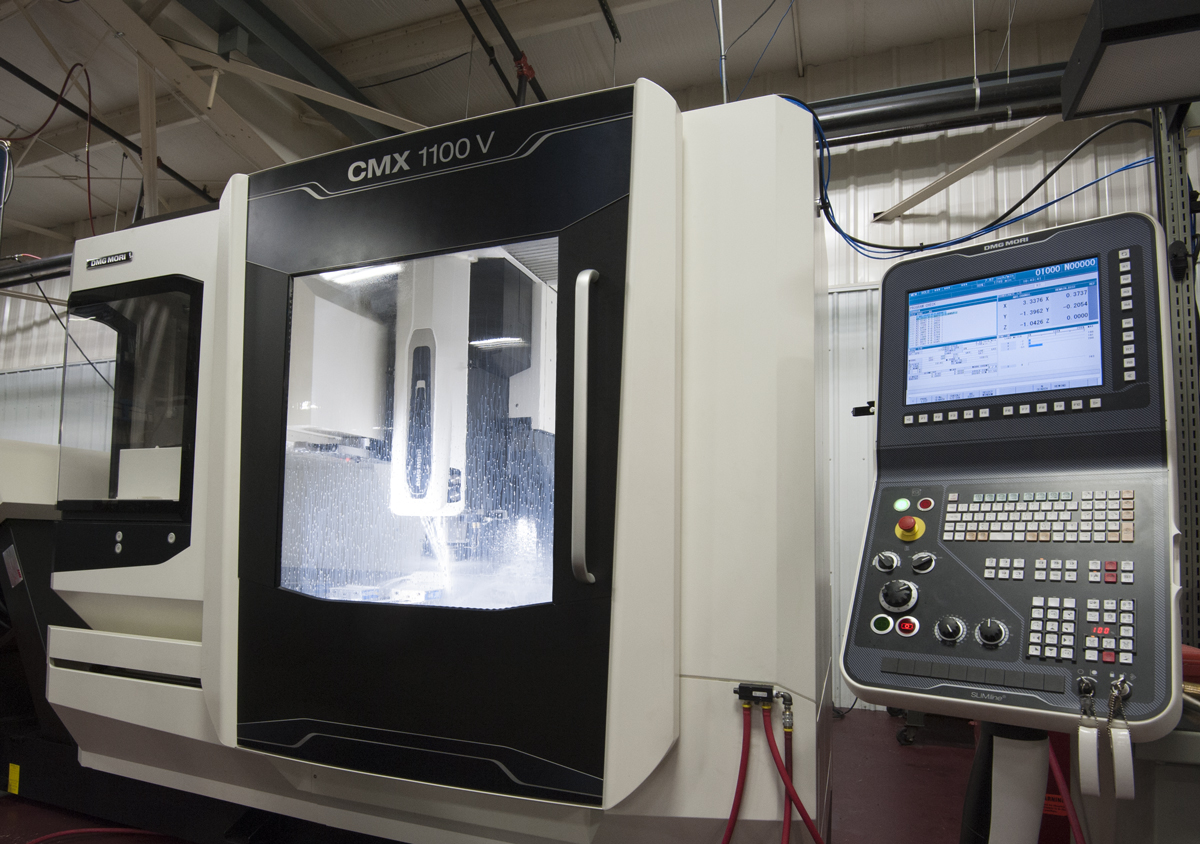

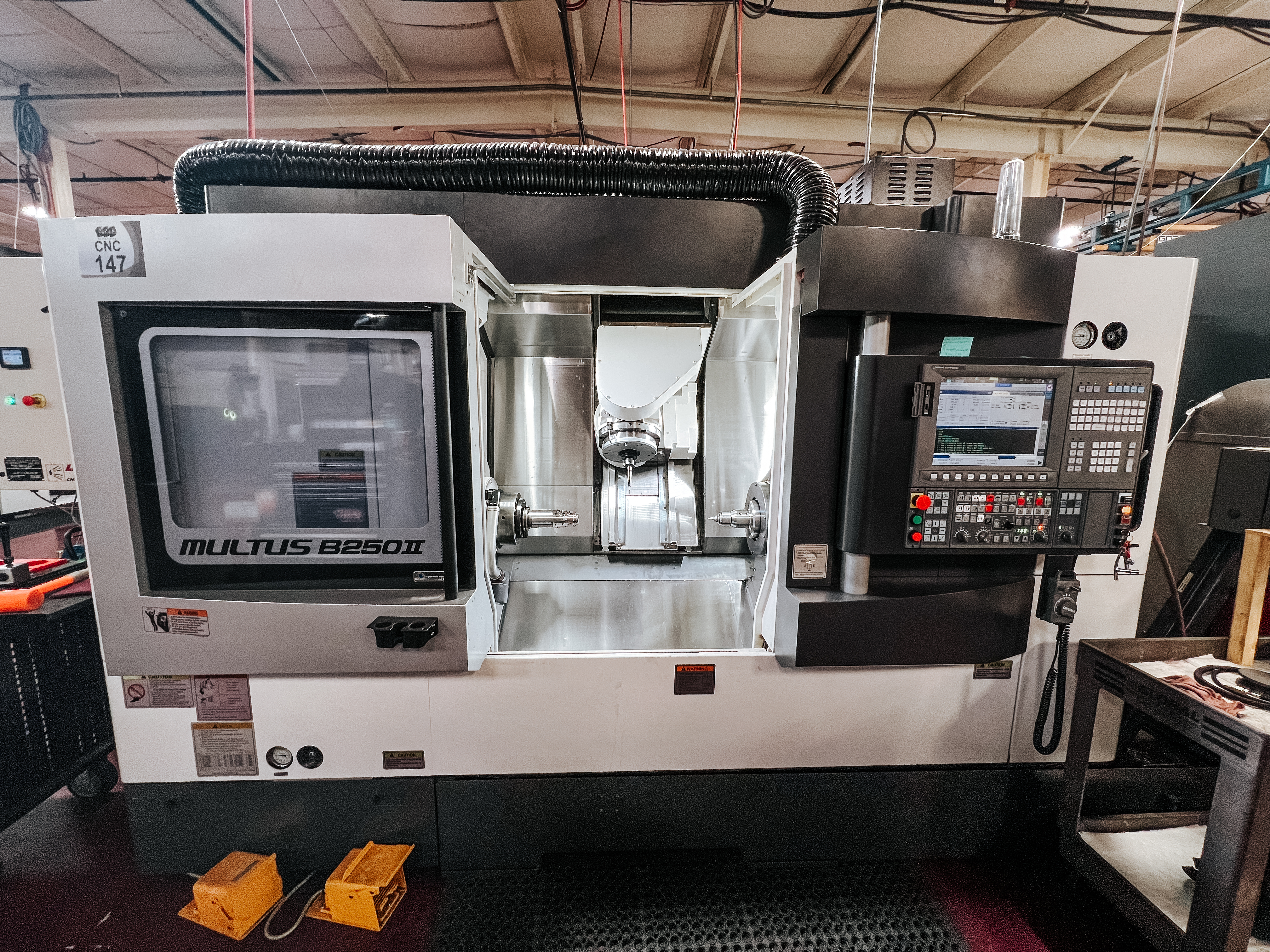

PDQ is continually investing in new equipment and utilizing the latest production machining technology to improve quality and efficiency.. CNC mill operators use SolidCAM to create programs directly from the SolidWorks model geometry to reduce errors. PDQ invested in specialized equipment with our products in mind. PDQ isn’t dependent on other shops for gundrilling or large plate grinding on fixture projects. Most integrated shank cutting tools are machined complete from the blank in our Mill Turn Centers. You can see more pictures of our equipment on our Google Tour.

PDQ Machine List

VMCs

| MAKE | YEAR | MODEL/TITLE |

| DOOSAN | 2018 | DNM 4500 |

| DOOSAN | 2018 | DNM 5700 |

| DOOSAN | 2019 | DNM 750 II |

| MAKINO | 2018 | PS 105 |

| OKUMA | 2021 | GENOS M460-VE |

| OKUMA | 2021 | GENOS M460-VE |

Lathes

| MAKE | YEAR | MODEL/TITLE |

| DMG MORI | 2017 | NLX 2500/700 |

| DOOSAN | 2015 | PUMA GT 2600M |

| DOOSAN | 2019 | PUMA 2600 Y |

| DOOSAN | 2012 | PUMA 2100 Y WITH LNS BAR FEEDER |

Finish Grinders

| MAKE | YEAR | MODEL/TITLE |

| OKAMOTO | 2023 | PRG8DXNC |

| OKAMOTO | 2014 | ACC32-80EX |

| OKAMOTO | 2013 | ACC12-24DX |

| OKAMOTO | 2014 | PRG6DX |

| OKAMOTO | 2016 | LINEAR 612B |

| OKAMOTO | 2016 | LINEAR 612B |

| OKAMOTO | 2010 | LINEAR 612B |

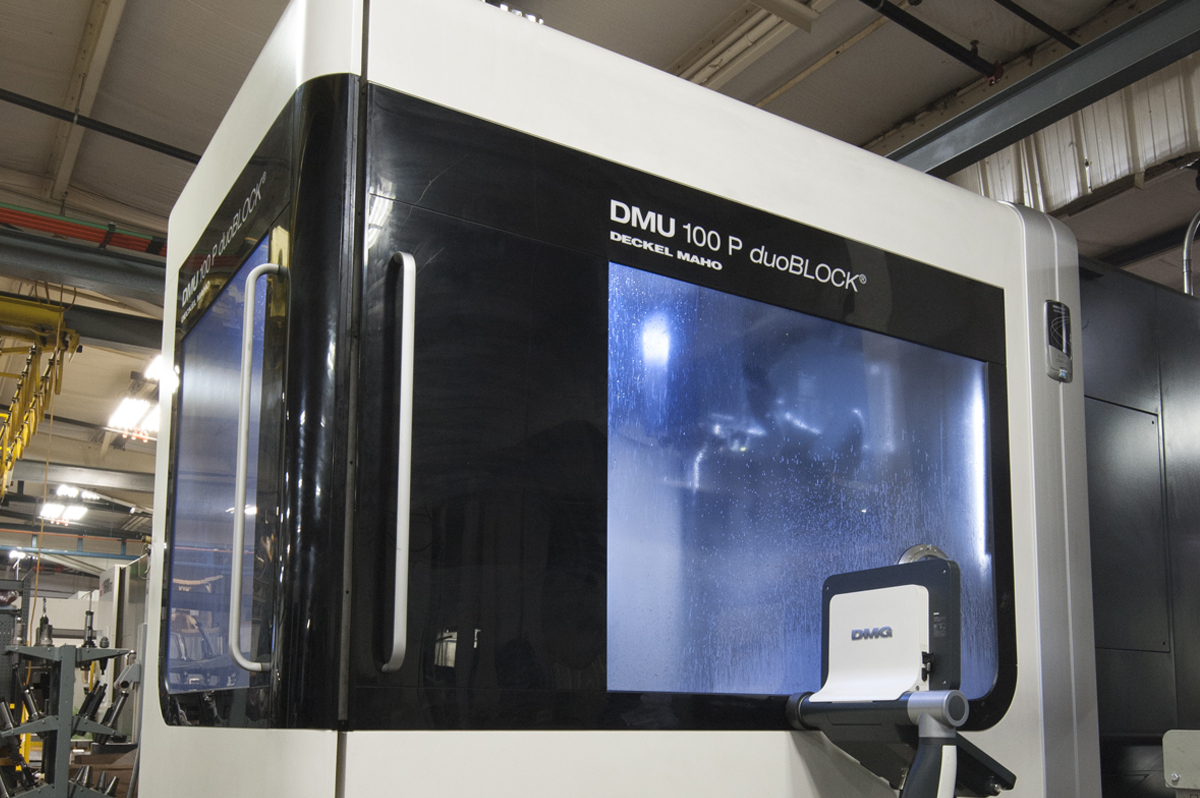

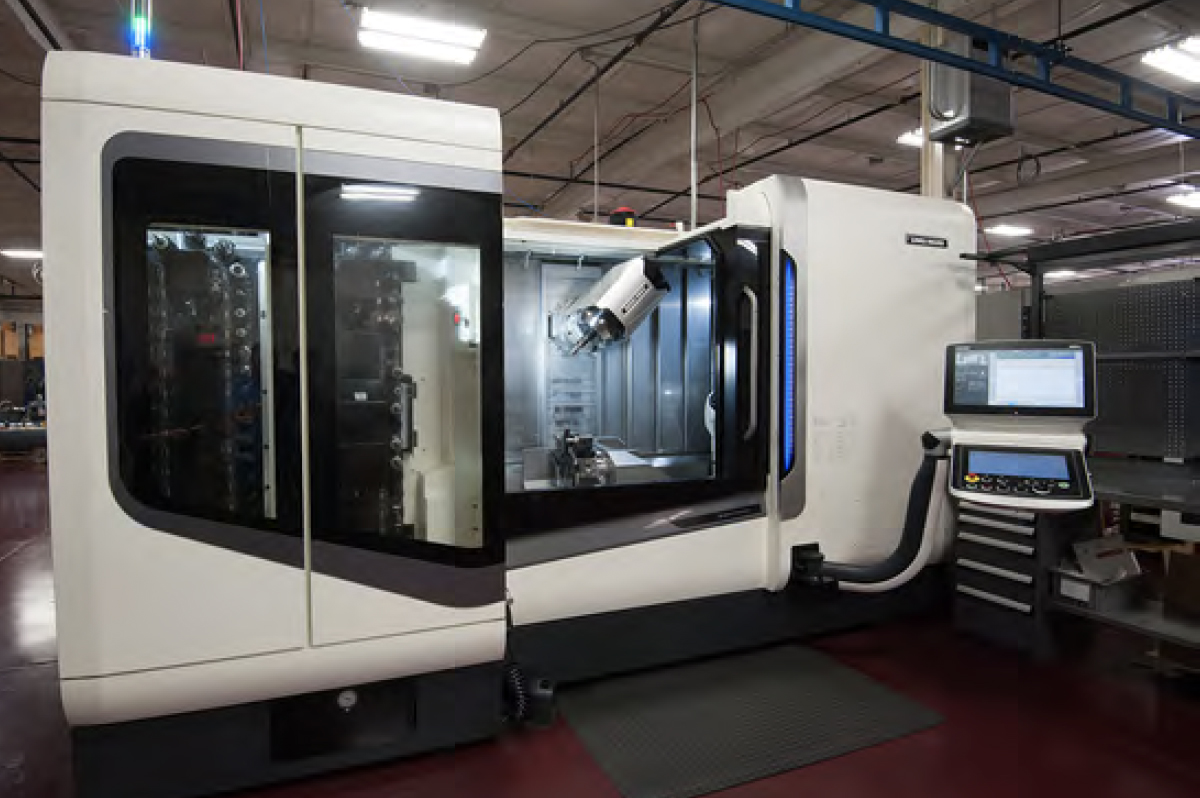

5 Axis Mills

| MAKE | YEAR | MODEL/TITLE |

| OKUMA | 2023 | MU8000 W/ 6 STATION PALLET POOL |

| DMG MORI | 2015 | DMU 50 |

| DMG MORI | 2014 | DMU 50 |

| DMG MORI | 2021 | DMU 50 |

| DMG MORI | 2016 | DMU 85 MONOBLOCK |

| DMG MORI | 2013 | DMU 100 P DUOBLOCK |

| MATSUURA | 2022 | MX-330 w/ PC-10 |

| MATSUURA | 2022 | MX-330 w/ PC-10 |

| MATSUURA | 2022 | MAM72-35V w/ PC-32 |

Mill Turns

| MAKE | YEAR | MODEL/TITLE |

| DMG MORI | 2014 | NTX 2000 |

| DMG MORI | 2016 | NTX 2000 |

| DMG MORI | 2020 | NTX 2000 |

| OKUMA | 2021 | MULTUS B250II |

| OKUMA | 2021 | MULTUS B250II |

| OKUMA | 2022 | MULTUS B250II |

| OKUMA | 2022 | MULTUS B250II |

Cutter Grinders

| MAKE | YEAR | MODEL/TITLE |

| ANCA | 2023 | MX7 WITH ROBOT LOAD |

| ANCA | 2022 | CPX WITH ROBOT LOAD |

| ANCA | 2020 | MX7 |

Other

| MAKE | MODEL/TITLE |

| ACER | E-MILL |

| ACER | E-MILL |

| BLANCHARD | 26HAD-48 |

| BLANCHARD | 22K-42 GRINDER |

| MAXIEM | 1515 WATERJET |