Assembly

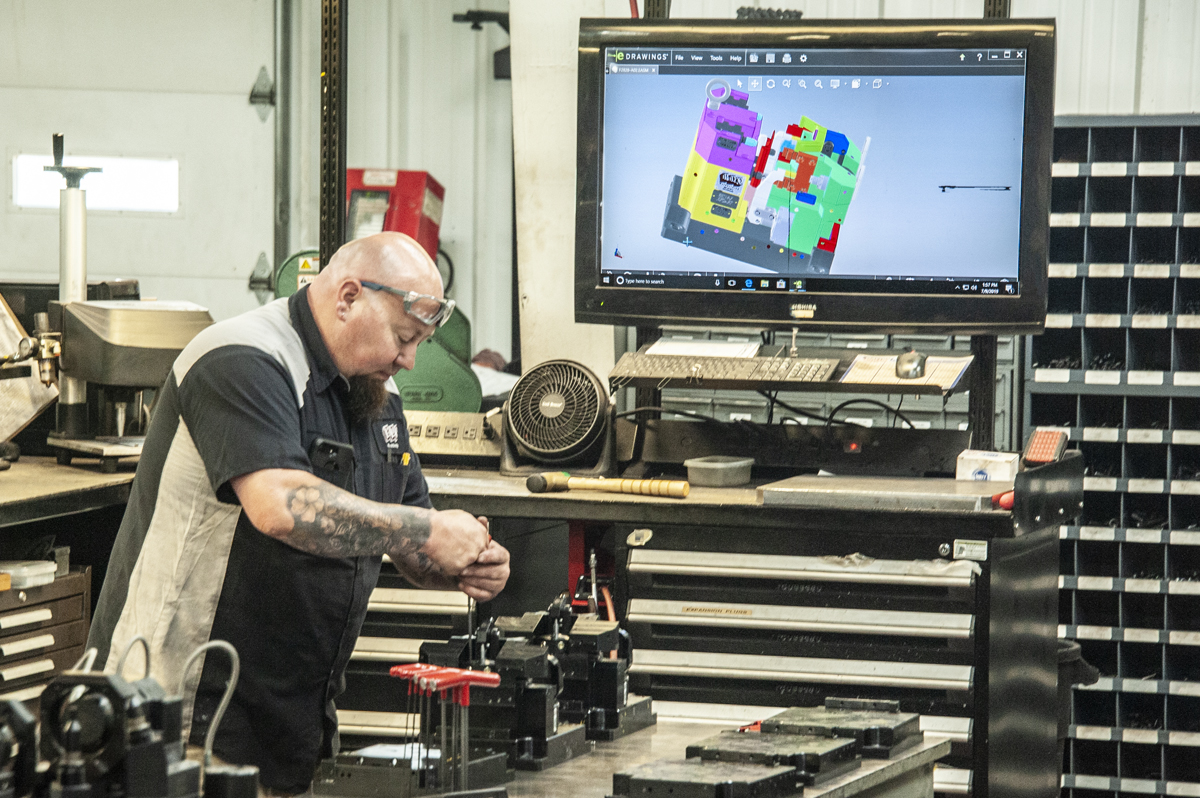

After machining, fixture components receive a black oxide finish for corrosion resistance and are laser etched for identification. Finished details then make their way to the assembly department where our skilled technicians carefully assemble each component. The assembly department features large monitors to display the fixture model, so technicians can easily determine fixture function. Ideally, the customer visits PDQ’s facility for the clamp test and final approval of a fixture. If that isn’t possible, PDQ Quality and Engineering will approve the fixture for shipment, and then it is crated and shipped.

Cutting tools receive black oxide and are also laser etched for identification. PDQ installs inserts in all individual indexable tools and can also provide you with a complete tooling package for any job to get you up and running quickly and painlessly. With our partners we can offer competitive pricing and a single source solution. We will build packages to your specification or you can provide a part print and let us do the rest. PDQ has the experience to put together an efficient and cost effective process. With years of experience with production tooling we help you streamline your processes.