Cutting Tool Manufacturers & Custom Cutting Tools

Custom Tooling Systems

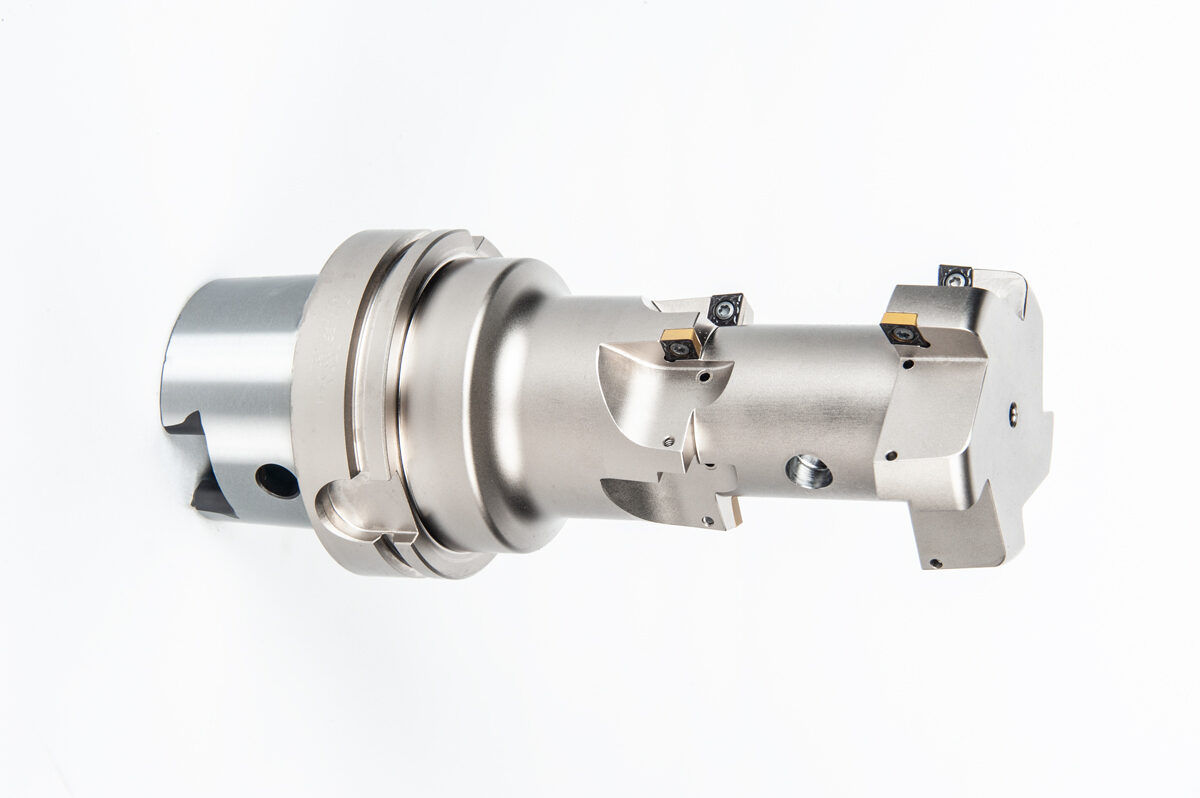

PDQ is an indexable cutting tools manufacturer that designs a wide range of custom cutting tools to suit your needs. We can design around your specific requests or we can recommend time saving, cost effective solutions to help make your project more profitable. Our engineering team will work closely with you through every stage of your project, providing conceptual designs for you to review. Once a final design of cutting tool is established and has been approved by the customer, your tool will be released to manufacturing.

PDQ keeps a large selection of HSK and CAT tool blanks in stock in order to respond quickly to our customer’s needs. PDQ takes great pride in our work, from our experienced engineering staff to our skilled machinists, and we work hard to ensure that our cutting tools meet the highest expectations. From our attention to detail in the machining process to the premium black oxide, we strive to produce the best cutting tools available.

Click The Part For More Details.

FAQ’s

How do custom tooling systems differ from standard tooling systems?

Standard tooling is usually manual and includes a grid plate with studs and strap or edge clamps and riser blocks to set manual stops. Custom tooling creates specific nesting for accurate and secure location and clamping of the part to be machined.

What advantages do custom tools offer over off-the-shelf solutions?

Excellent accuracy, high production counts, and the least number of operations to completely machine the part to print.

How can indexable tools benefit my machining processes?

Indexable tooling is a great way to save time and money and improve overall machining efficiency. It involves the use of interchangeable cutting inserts that are mounted on a tool body. These inserts can be easily replaced once they have worn out or become dull.

Are custom cutting tools compatible with all types of machines?

Not necessarily. We specialize in tooling solutions, please contact us!

How does cutting tool technology impact the performance of custom tools?

The advances in engineering are incredible. We can help decide the best tool for your machining application.

How do I ensure I’m getting the best quality from cutting tool manufacturers?

We only use top quality suppliers. They evaluate and test their products for wear and failure and offer the best they manufacture.

In what industries or applications are custom cutting tools most beneficial?

Most any manufacturing environment that machines materials from blanks or raw stock; any type of metals, wood, plastics, and composites.

How do cutting tool technologies evolve to meet industry demands?

They are developed for the needs of specific part geometry / materials and high quantity production.

What is the process for ordering custom tools tailored to specific needs?

Please contact our sales team and we will meet with you to discuss your project and needs.

How do indexable tools compare in terms of cost and performance?

They are a great investment for high production machining. Cost saving as you replace only the worn inserts instead of the complete tool.

Are there maintenance considerations specific to indexable tools or custom cutting tools?

Using the proper coolants / speeds and feeds. Also noting to change inserts as they wear.

How do cutting tool manufacturers ensure the longevity and durability of their products?

Thorough testing of their products and quality checks in production.

Are there any sustainability practices associated with cutting tool technologies?

We strive to continuously improve our custom tooling as we look forward to supporting our customers with the best product available.